MIG WIRES

SS welding using Gas Metal Arc Welding (GMAW) or commonly called Metal Inert Gas (MIG) welding is popular in applications where Robotics is used or in Shop floor jobs where continuous weld through machines are preferred.

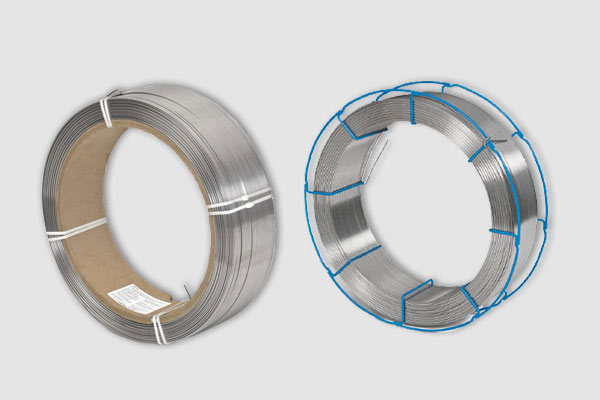

MIG wires are produced in various types of spools as well as in drum packing for continuous welding. We also provides customized packing and packaging of MIG wires. Whatever the application, our Stainless Steel MIG Wires bear a stamp of authority in the industrial circle. Our wires are manufactured as per the specifications of the American Welding Society (AWS).

Our MIG WIRES are manufactured in SS grades 307Si, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316L, 316LSi, 317L, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209, 2597, 630 and nickel grades , NiCr-3 & NiCrMo-3 with bright, matte or semi bright finishes. Our stainless steel MIG wires are manufactured in sizes ranging from 0.60 mm to 1.60 mm diameter.

Grades

307Si, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316L, 316LSi, 317L, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209, 2597, 630, NiCr-3 & NiCrMo-3 *Also offered in equivalent DIN Standard

PACKAGING ON SPOOLS

We also offer “Customized Packaging & Labelling Solutions” as per requirement.

| SIZE | STANDARD SPOOLS | ||||

|---|---|---|---|---|---|

| NM | INCH | SD 300/BS300 | SD 200/BS200 | SD 100 | |

| 0.60 | 0.025 | 10 Kg. – 20 lbs. | |||

| 0.80 | 0.030 | 12.5 Kg./25 lbs. 15 Kg./30 lbs. – 33 lbs. |

5 Kg./10 lbs. | 1 Kg./2 lbs. | |

| 0.90 | 0.035 | ||||

| 1.00 | 0.040 | ||||

| 1.20 | 0.045 | ||||

| 1.60 | 0.062 | ||||

PAIL PACKING SYSTEM FOR AUTOMATIC WELDING

MIG Wires in Fiber Drums of 100-125 kg (200-250 lbs)/200-225 kgs (450 – 500 lbs) available for high productivity GMAW process and robotic applications.

- Increase in productivity : With less down time compared to standard spools

- Less wear on welding machine parts : No twist pay-off system.

- Clean conditions : No contamination from the shop environment

- Low space requirement : The drum diameter is only 510 mm

- Short setup time : Adapt quickly and easily to any conventional feeder

We also offer ‘Customized Packaging & Labelling Solutions’ as per requirement.

FOR GMAW (MIG) PROCESS

DIAMETER

| mm | 0.60 | 0.80 | 0.90 | 1.00 | 1.20 | 1.60 |

|---|---|---|---|---|---|---|

| Inch | 0.025 | 0.030 | 0.035 | 0.040 | 0.045 | 0.062 |

*Surface Finish : Bright, Matte & Semi Bright